The need and importance for reliable and accurate quality control have increased significantly as the latest technologies have gone beyond the limits of manufacturing. Given the contemporary manufacturing landscape, conventional methods of metrology use are not ideal. This is where 3-dimensional metrology services fill in the void. 3D metrology has gained a reputation for offering an efficient solution that suits contemporary challenges and also redefines every possibility in metrology. Even a few years back, CMM or Coordinate Measuring Machines was the preferred tool for metrology-associated tasks. Today, 3D metrology services have gradually overshadowed the market of CMM tool applications.

Why utilize 3D metrology services?

With the increasing complexity of technology, the limits of engineering are pressed. It leaves very little space for errors, and the focus is more on the reliability factor. Conventional tools like CMMs are not anymore adequate because they are not fast, and don’t represent a picture of the complicated components and parts used in the modern manufacturing sector. Some of the prime reasons for utilizing 3D metrology services are:

More cost-effective than CMM tools

A 3D metrology tool is way cheaper than a traditional tool like CMM when it comes to measurement and quality control of modern manufacturing parts and components. Moreover, one will come across a plethora of 3-dimensional metrology systems that fit any metrology budgeting.

A wide measurement reporting

One of the highlighting benefits of metrology services is that they can yield a wide array of data points when a CMM tool fails to maintain extensive coverage. Hence, the 3D metrology techniques can deliver a complete presentation of the dimensions of the parts used in the manufacturing industry.

Efficient inspection

It is the nature of the 3D metrology service that the parts and components are measured and inspected during the production process. Thus, the in-process evaluation is beneficial as it can identify errors and misfits if any.

The working mechanism of 3D metrology services?

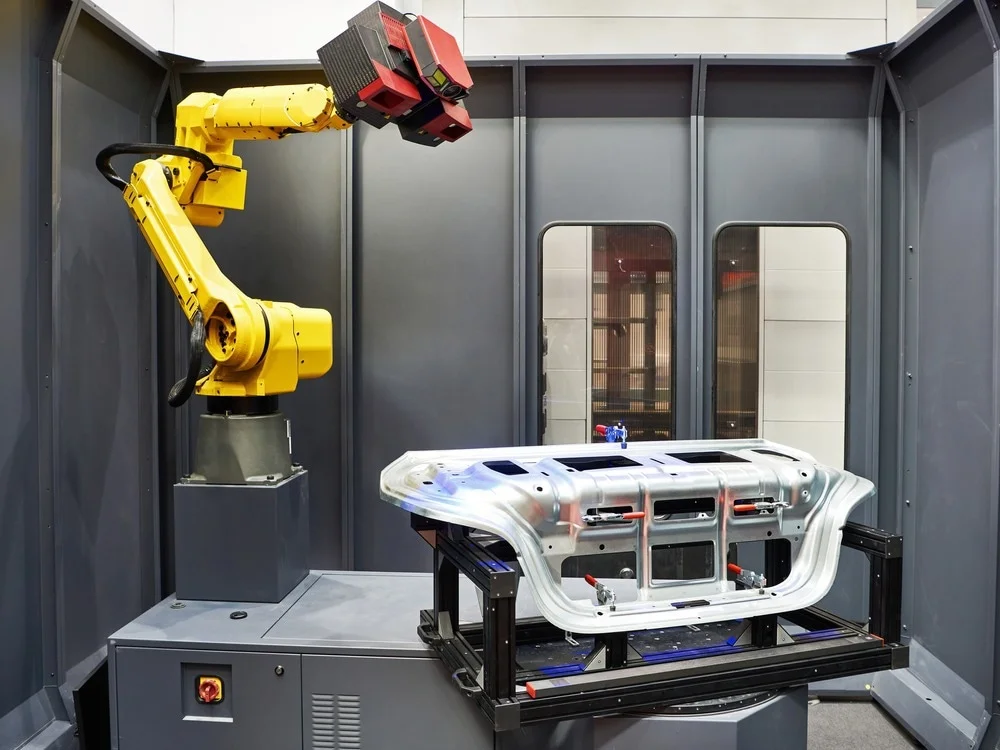

3-dimensional metrology creates a complete 3D presentation of the parts and components measured and evaluated. It is then pictured with a colored map and recognizes the out-of-specification parts when compared to the standard dimensions. This data gets incorporated into the new parts of manufacturing. This is done to enhance the parts and maintain the highest precision level. The steps included in the 3D metrology scan are given below:

Sensor aligning and measuring

The sensor is located in front of the scanner. While scanning, it is the sensor that moves around the tool freely and yields a data set.

Inspecting

The data accumulated is then compared to the standard specified CAD dimensional data. It determines the actual dimensions originating from the specified data.

Outcomes

In the final stage, a set of results is generated that presents the most accurate challenging areas. Thus, 3D metrology services help determine the problem areas so that easy solutions can be derived.

Conclusion

3D metrology services are increasingly becoming the most favored technology for dimensional measurement and quality control in the manufacturing industry. Experts are researching the ins and outs of the technology to understand more about them and thereby incorporate them into industrial use.