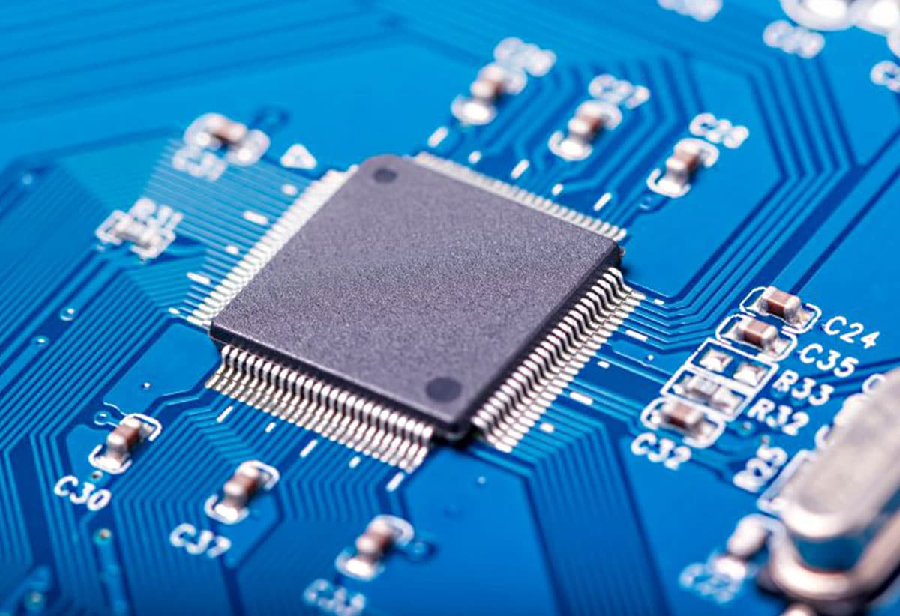

The core of any electronic equipment or device is PCB. Without the PCB, it is not possible to conceive of an electronic product. The first major effort every electronic equipment manufacturing company must take is to put in place the best PCB sourcing model. Your production floor must have a regular supply of PCBs. There could be no shortage of PCBs for your production to continue.

Just because you want to continue with your production, you cannot source your PCBs from some random stores. You need to identify the best PCB fabrication company to take care of your requirements. Those who lack the required experience in this field, select their PCB manufacturing companies just based on the quotes that they receive. You need to be sure that you are sourcing your PCBs at the most competitive prices but this does not mean that the quality of the PCBs could be compromised. If the PCB quality were to be compromised then your efforts on sourcing PCBs at the lowest prices would only turn out to be counterproductive. You will not save any money in the process but instead you will end losing more money than what you have actually saved.

Given the fact that your PCBs make the heart of your electronic device, if there is something wrong with the quality of the PCBs then your device itself will not function as expected. Your device will become unreliable. Poorly assembled PCBs will experience heating issues and this could even result in accidents. Your PCB assembly company should ensure that the components are installed professionally. The PCBs must be fully tested after assembly. You must work only with companies that are ready to deliver fully tested PCBs. So, if you are going to select your PCB suppliers just based on the quote without keeping all these factors in mind then you will definitely regret your choices down the line.

There are hundreds of PCB manufacturers in the industry; among them you will find all types of PCB manufacturers, the good ones as well as the not so good ones. It would be your mistake to leave the good ones and select the not so good ones. You would not want to make such mistakes because down the line, it would be your brand reputation that will take a hit. Once the brand reputation is damaged then it takes a lot of time to recover from the damage. You need to work ten times harder to get back the confidence and the trust of your customers. You could easily avoid all these challenges and issues by focusing on your screening process and in selecting only the most trusted suppliers in the industry. You will certainly not regret taking the time to review multiple suppliers. You are not required to do this for every batch. Only the first time such a long and tedious screening is essential. Look for the most trusted long term PCB supplier.

ChinaPCBOne Technology LTD. is the author of this article on PCB fabrication. Find more information, about PCB assembly.