Introduction to Composite Testing

Composite materials have revolutionized engineering across industries like aerospace, automotive, construction, and marine. Their strength, durability, and lightweight properties make them ideal for performance-focused applications. However, to ensure the reliability and safety of these materials, composite testing becomes crucial.

In this article, we’ll explore what composite testing is, its major types, why it’s important, how it’s done, and what standards guide the process.

What Is Composite Testing?

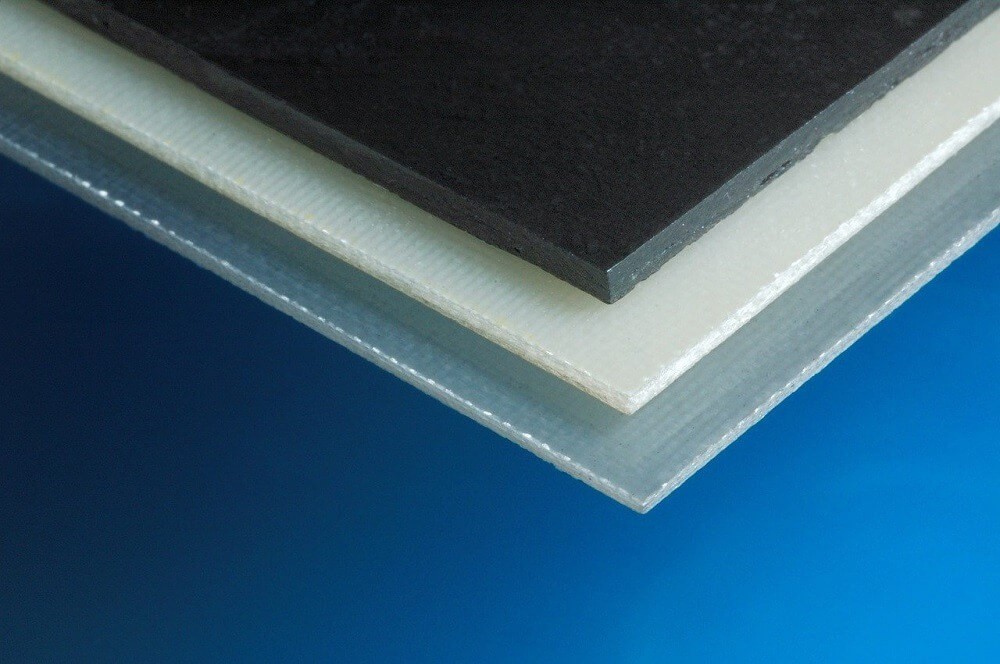

Composite testing refers to a series of tests performed to assess the physical, mechanical, and thermal properties of composite materials. Composites are materials made by combining two or more constituent materials with significantly different physical or chemical properties—such as carbon fibers and epoxy resin.

Testing ensures that these materials meet quality standards and function as expected under different conditions, such as high stress, extreme temperatures, and environmental exposure.

Why Is Composite Testing Important?

Composite testing plays a critical role in:

- Quality Assurance: Verifying that the materials meet product specifications.

- Safety: Preventing structural failures in sensitive applications like aerospace and automotive.

- Product Development: Helping engineers choose the right composite for a particular application.

- Regulatory Compliance: Meeting international standards like ASTM, ISO, or DIN.

- Failure Analysis: Understanding causes of material breakdown or product malfunction.

Common Types of Composite Testing

Composite materials are subjected to various types of tests. Here are the most common ones:

1. Tensile Testing

Tensile testing measures how much a material can be stretched before breaking. It helps determine:

- Tensile strength

- Elastic modulus

- Elongation at break

2. Compression Testing

This test is used to check how well a composite material can withstand a crushing force without failing.

3. Flexural Testing (Bending)

Flexural tests evaluate the ability of the material to resist deformation under load. It’s especially important for beam- and panel-shaped parts.

4. Shear Testing

Shear testing identifies the material’s resistance to forces that cause internal sliding between layers (interlaminar shear strength).

5. Impact Testing

This test checks how much energy a composite can absorb during sudden loading or collisions, essential for aerospace and automotive applications.

6. Fatigue Testing

Fatigue testing simulates repeated loading cycles to see how long the material can last before failure.

7. Thermal Testing

These tests measure thermal conductivity, heat resistance, and expansion behavior, critical for materials exposed to high temperatures.

8. Non-Destructive Testing (NDT)

NDT methods such as ultrasonic testing, X-ray, and thermography help detect internal defects like delamination or voids without damaging the sample.

Composite Testing Methods and Equipment

Here’s a brief look at the popular testing methods and tools used:

| Test Type | Method | Equipment |

| Tensile | ASTM D3039 | Universal Testing Machine (UTM) |

| Compression | ASTM D695 | Compression Fixture with UTM |

| Flexural | ASTM D790 | 3-Point Bending Fixture |

| Shear | ASTM D2344 | Short Beam Shear Fixture |

| Impact | ASTM D256, ISO 179 | Izod or Charpy Impact Tester |

| Thermal | ASTM E1356, ISO 11357 | DSC, TGA Analyzers |

| NDT | Ultrasonic, X-ray | Ultrasonic Flaw Detectors, CT Scanners |

Industries That Rely on Composite Testing

1. Aerospace

Aircraft components like wings, fuselage parts, and turbine blades require highly reliable composites. Testing ensures that they meet weight and strength requirements.

2. Automotive

Car manufacturers use carbon fiber and fiberglass in body panels and structural parts. Composite testing ensures performance and crash safety.

3. Construction

Composites like FRP (Fiber Reinforced Polymer) are used in bridges, buildings, and reinforcements. Testing confirms they meet load-bearing and environmental resistance criteria.

4. Marine

Boats and ships rely on composites for hulls and decks. Saltwater resistance, impact strength, and fatigue properties are key focus areas.

5. Sports and Recreation

High-performance equipment like tennis rackets, bicycles, and helmets uses advanced composites. Testing ensures safety, durability, and performance.

International Standards for Composite Testing

Several standards guide how composite materials should be tested:

- ASTM (American Society for Testing and Materials)

- ASTM D3039: Tensile Properties of Polymer Matrix Composites

- ASTM D7264: Flexural Properties

- ASTM D2344: Interlaminar Shear Strength

- ISO (International Organization for Standardization)

- ISO 14125: Flexural Properties

- ISO 527-4/5: Tensile Testing

- ISO 11357: Thermal Testing

- DIN (German Standards)

- DIN EN ISO 179: Charpy Impact Testing

Adhering to these standards ensures global quality and regulatory compliance.

Challenges in Composite Testing

Despite its advantages, composite testing comes with challenges:

- Anisotropy: Composites behave differently in different directions, requiring multi-axis testing.

- Complex Structures: Components are often curved or layered, making it difficult to prepare standard samples.

- Environmental Sensitivity: Humidity and temperature can influence results, requiring controlled test environments.

- Cost: Advanced testing equipment, especially NDT tools, can be expensive.

Future Trends in Composite Testing

The industry is moving toward more automated, intelligent, and efficient testing:

- AI-Based Defect Detection: Machine learning models are being trained to detect flaws from NDT scans.

- Digital Twins: Virtual replicas of materials allow simulation-based testing.

- Portable Testing Equipment: Field testing is becoming easier with handheld ultrasonic and thermal analyzers.

- Sustainable Testing: Focus on testing recyclable and bio-based composites for greener applications.

FAQs About Composite Testing

Q1. What is the most common composite material tested?

Answer: Carbon fiber reinforced polymer (CFRP) is the most commonly tested composite, especially in aerospace and automotive industries.

Q2. Can composite materials fail without warning?

Answer: Yes, some composites may fail without visible signs, which is why non-destructive testing (NDT) is critical for early detection.

Q3. How often should composite testing be done?

Answer: Frequency depends on the application. Critical applications like aerospace may require testing after every batch, while construction might test by project phase.

Q4. Are composite testing standards different across countries?

Answer: While international standards like ISO are widely accepted, some countries also follow local standards like ASTM (USA) or DIN (Germany).

Q5. What are the costs associated with composite testing?

Answer: Costs vary based on the type of test, equipment used, and the number of samples. Basic mechanical tests may cost a few hundred dollars, while NDT can be more expensive.

Conclusion

Composite testing is a vital process that ensures materials are safe, reliable, and performance-ready. Whether it’s a carbon fiber aircraft wing or a fiberglass bridge component, proper testing methods validate the material’s integrity. As industries push the boundaries of lightweight and durable design, the role of composite testing will continue to grow.

By understanding the different types of composite tests, applicable standards, and evolving trends, engineers and manufacturers can make smarter, safer material choices for a wide range of applications.